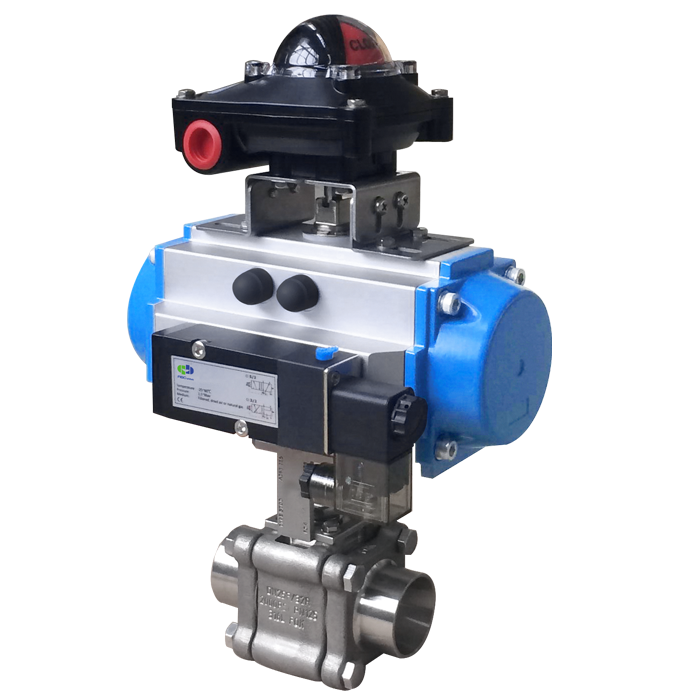

概述

B33系列高性能三片体球阀设计用于高压,防火,执行器连接灵活,循环寿命长,简单现场维护等多项高性能服务。三片体设计使得维修方便,无需拆卸阀盖。这种阀门的对焊、承插焊和螺纹很受欢迎。

特点

• 三片体外开式设计,便于现场维护全通径和缩径都可生产

• 精铸阀体,无铸造缺陷,表面细致

• 防脱出阀轴

• 聚四氟乙烯加25%碳纤维阀座标准适用于高压力和高温度,更耐磨损,可提供多种阀座和密封材料

• 球槽内有减压孔

• 符合ISO5211的安装带中心定位

• 用于球轴体的防静电装置

• 球形浮动阀杆带来更高的循环寿命

• 可提供防火安全型

• 完全封装的阀体密封允许在无需拆卸的情况下进行焊接

高性能三片体球阀 ★★★★

高性能三片体球阀 ★★★★